Podrobné informace k produktu

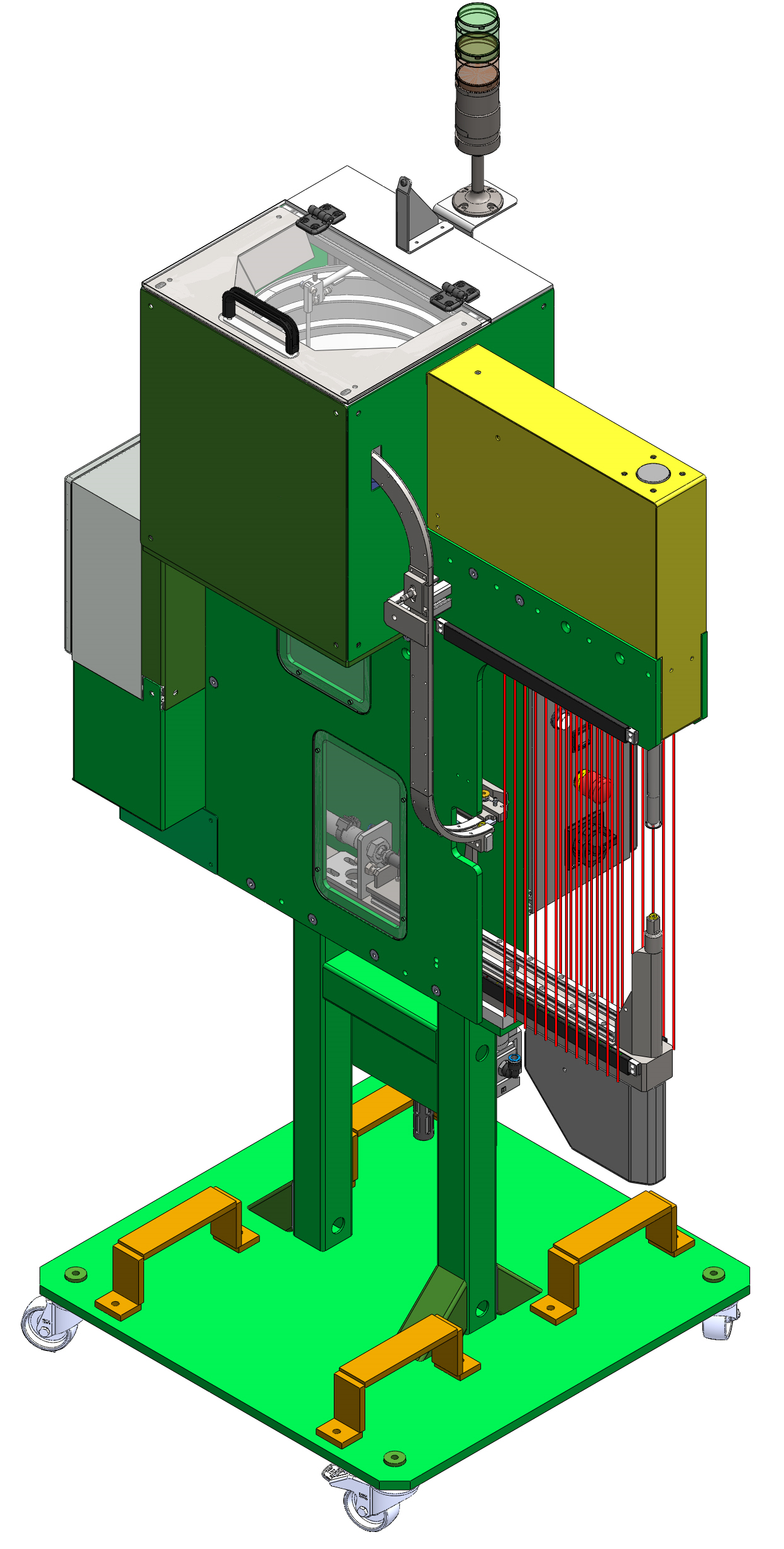

Automatic feeding system - Motor case

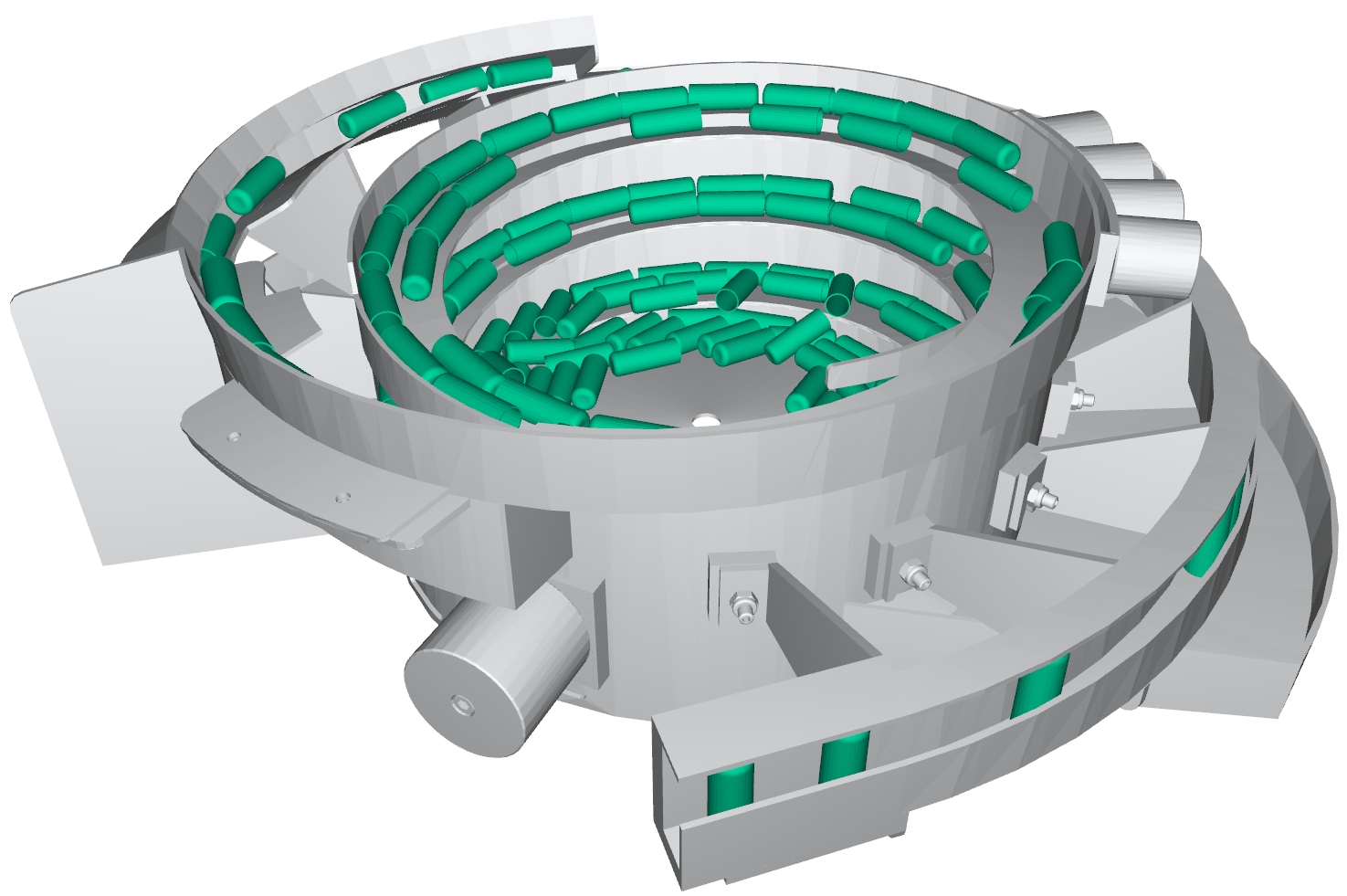

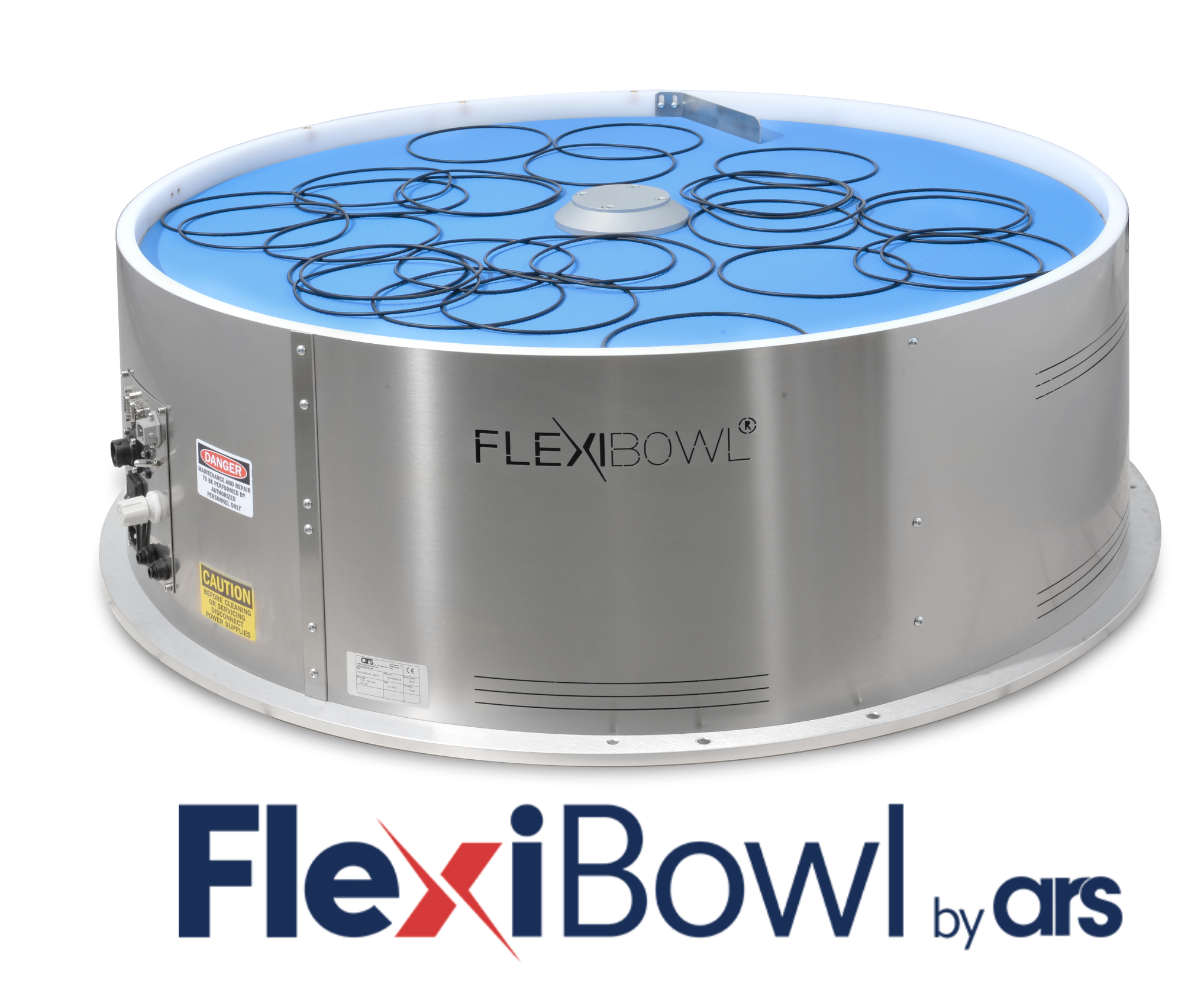

Vibration feeder/sorter system based on RNA SRC-N 400 drive (left or right execution)

- USJ 400 triangle setup plate, for mounting the feeder by 3 screws( set up within +/- 10mm)

- AAG-R 400 adapter central plate for radial 8 screws bowl mounting

- Sorting bowl stainless steel stepped/ conical/ cylindrical - parts orientation due to request

- Surface coating - glued-in sheets/carpets

- Output guiding part -machined ( for precise threshold between bowl and linear rail)

- A compressed air may be used for sorting. Air treatment unit with reduction valve, sol.valve and throttle valves

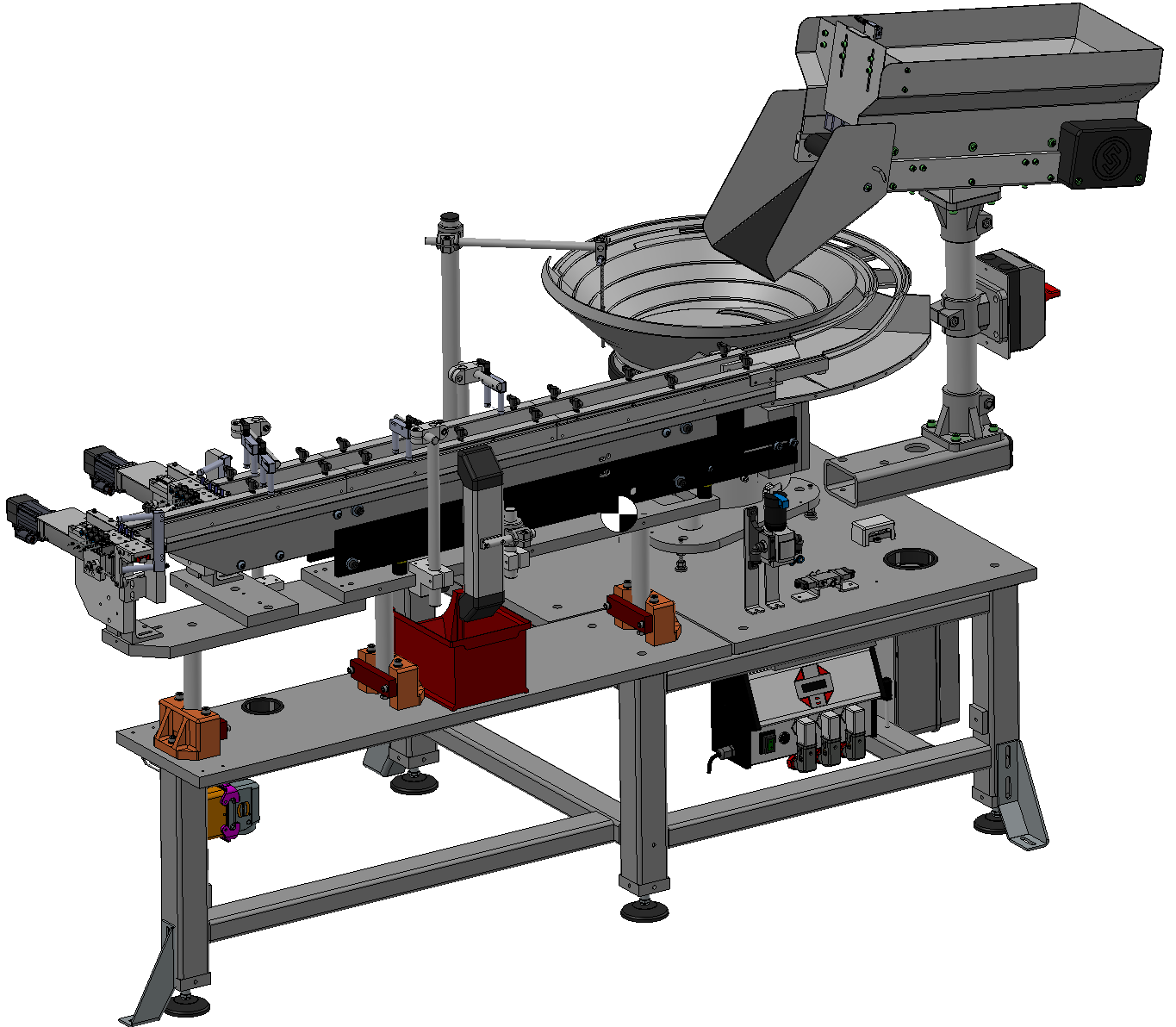

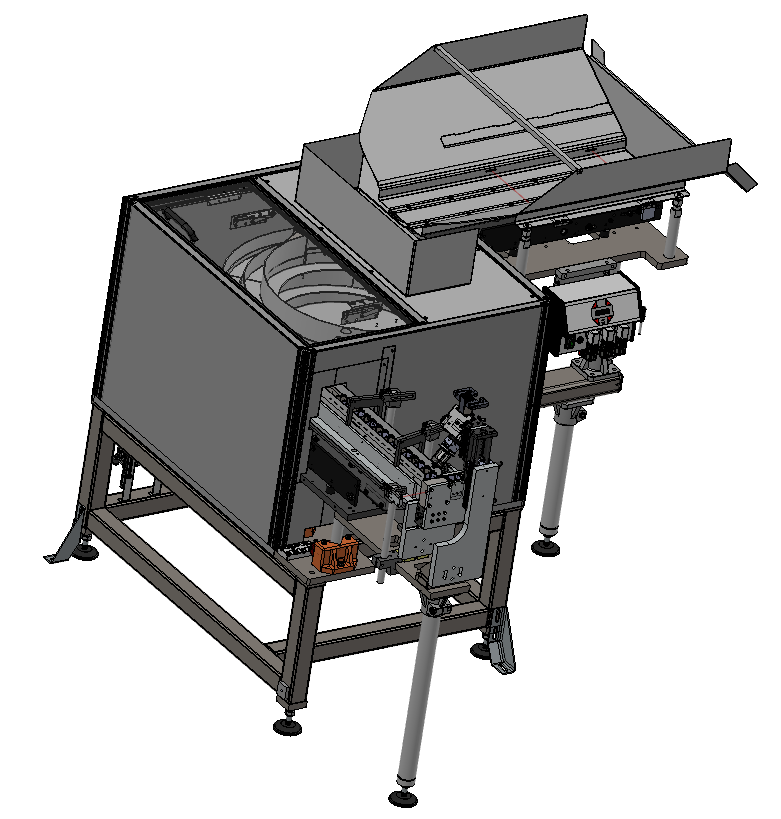

Guiding cumulation and parts swing rail on vibration drive based on RNA SLL 800 type

The linear drive of this applicattion hangs cases over their flange

- Track length aprx. 1,2mm

- The RNA SLL800-1000 drive ( stand included)

- Guiding elements st.steel or nitrided. optional easy opening top guiding

- Level of parts buffer tracked by Balluff opt. sensor

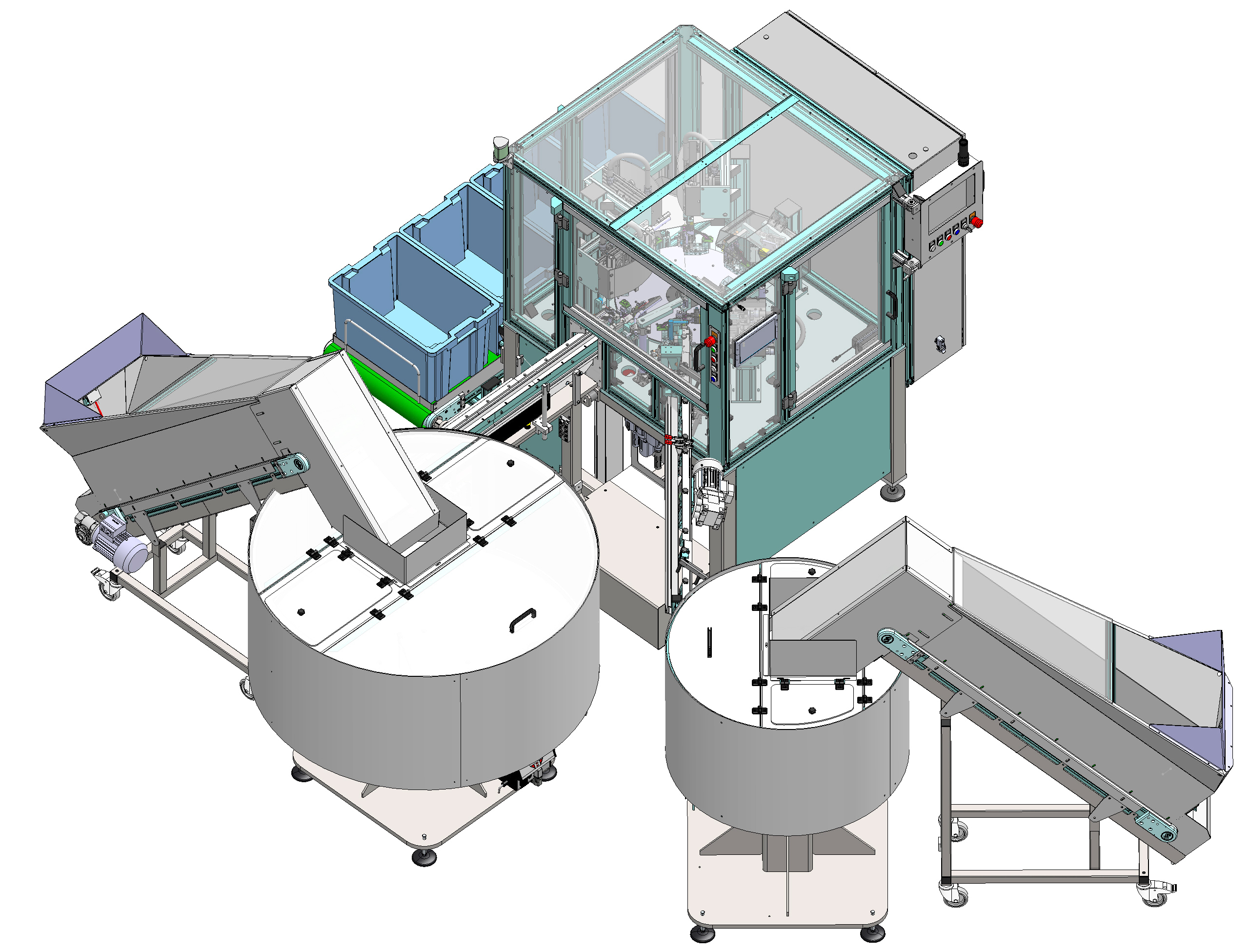

The buffer of parts is provided by vibration bunker/trough that evenly spreads parts filled by magnetic crane manipulator (offered by another quote)

This bunker stands on own support connected with main frame of feeder

Its volume is aprx. 50-60 l – to meet space-wise the size of magnet.

The end separation unit

- parts buffered in a linear track enter an end unit where are separated one by on, by pneumatic manipulator.

- The case is moved to the side, apart of pressure of other parts, at first

- Separation is provided turn/swing Festo drive, placed on top of part on which is gripper placed on guided Festo cylinder

- This gripper goes inside of motor case, grab, lift and turn it up – flange down bottom up.

- Sensorics, pneumatic included ( full function provided)

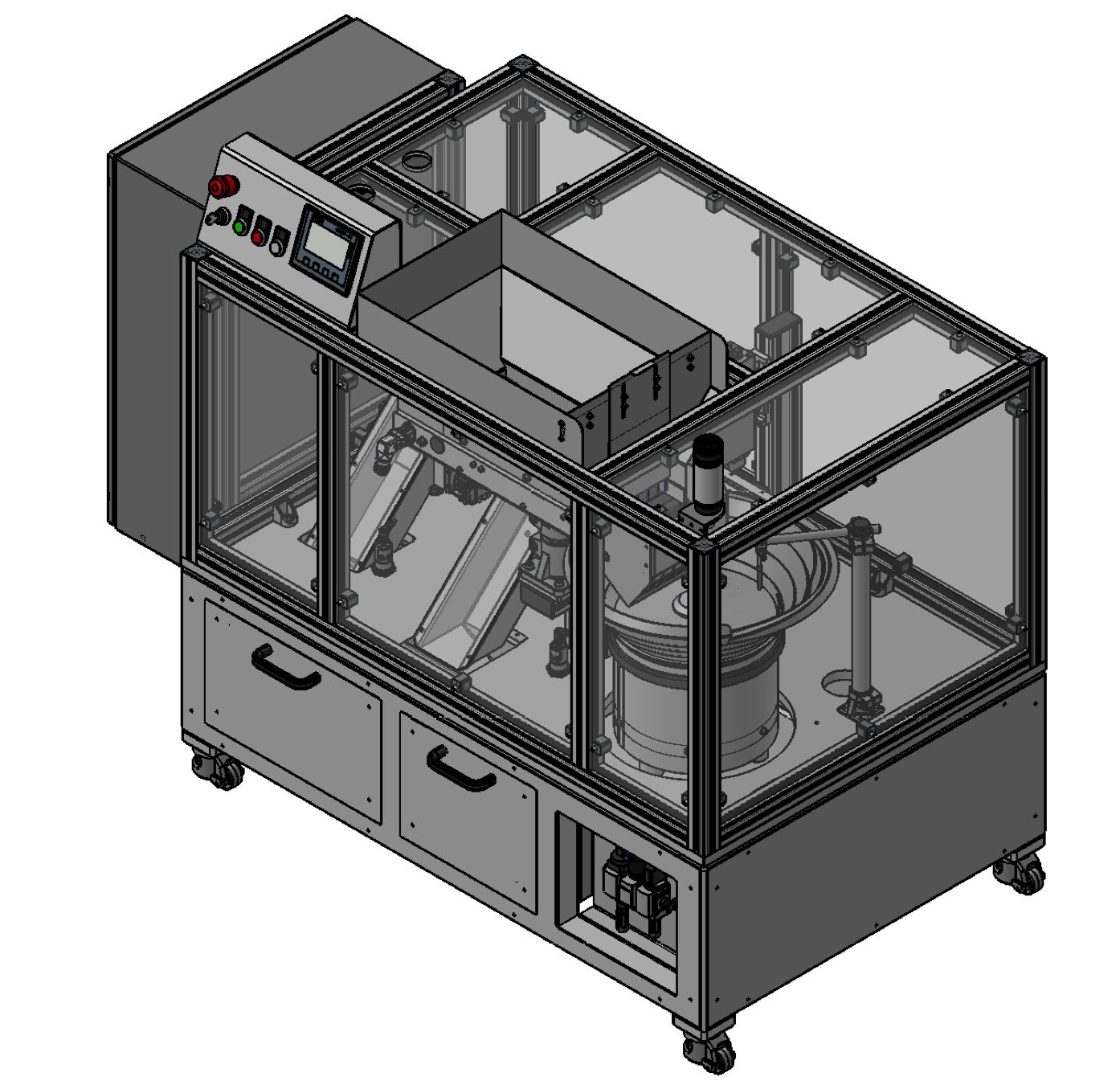

Electrical equippment:

- The ESK 2002 regulator takes care of 3 power outputs (round, linear drive and drive of bunker) same as logic of bowl level sensor and linear line sensor.

- Machine equipped by a small electrocabinet with the main supply, ON/OFF switch, 24V 10A supply.

- The end unit must be controlled by PLC of master machine.

- Interface through ProfiNet Balluff communication hub.

- Wiring diagrams done in EPLAN SW.

Noise cover in size of RNA SRC-N 400 drive

- fibre glass cover on top. St.steel frame guiding for parts falling from filling device.

Base installation plate / construction

- Steel painted plate 12mm, frame welded 4mm/60 closed profiles

- A size and shape can be discussed

- Painted by RAL shade by customer’s request

- USJ 400 triangle setup plate, for mounting the feeder by 3 screws( set up within +/- 10mm)

- AAG-R 400 adapter central plate for radial 8 screws bowl mounting

- Sorting bowl stainless steel stepped/ conical/ cylindrical - parts orientation due to request

- Surface coating - glued-in sheets/carpets

- Output guiding part -machined ( for precise threshold between bowl and linear rail)

- A compressed air may be used for sorting. Air treatment unit with reduction valve, sol.valve and throttle valves

Guiding cumulation and parts swing rail on vibration drive based on RNA SLL 800 type

The linear drive of this applicattion hangs cases over their flange

- Track length aprx. 1,2mm

- The RNA SLL800-1000 drive ( stand included)

- Guiding elements st.steel or nitrided. optional easy opening top guiding

- Level of parts buffer tracked by Balluff opt. sensor

The buffer of parts is provided by vibration bunker/trough that evenly spreads parts filled by magnetic crane manipulator (offered by another quote)

This bunker stands on own support connected with main frame of feeder

Its volume is aprx. 50-60 l – to meet space-wise the size of magnet.

The end separation unit

- parts buffered in a linear track enter an end unit where are separated one by on, by pneumatic manipulator.

- The case is moved to the side, apart of pressure of other parts, at first

- Separation is provided turn/swing Festo drive, placed on top of part on which is gripper placed on guided Festo cylinder

- This gripper goes inside of motor case, grab, lift and turn it up – flange down bottom up.

- Sensorics, pneumatic included ( full function provided)

Electrical equippment:

- The ESK 2002 regulator takes care of 3 power outputs (round, linear drive and drive of bunker) same as logic of bowl level sensor and linear line sensor.

- Machine equipped by a small electrocabinet with the main supply, ON/OFF switch, 24V 10A supply.

- The end unit must be controlled by PLC of master machine.

- Interface through ProfiNet Balluff communication hub.

- Wiring diagrams done in EPLAN SW.

Noise cover in size of RNA SRC-N 400 drive

- fibre glass cover on top. St.steel frame guiding for parts falling from filling device.

Base installation plate / construction

- Steel painted plate 12mm, frame welded 4mm/60 closed profiles

- A size and shape can be discussed

- Painted by RAL shade by customer’s request

Kompletní podávací systémy řady 250

Automatic feeding system - Motor case

V24-064-2-00-000

Skladem 0 ks

Pro nákup zboží je nutná registrace.

| Kód dílu: | V24-064-2-00-000 |

|---|---|

| Dodací lhůta: | 0 |

| Jednotka dodací lhůty: | Dny |

Související produkty

-

Skladem 0 ks

Pro nákup zboží je nutná registrace.