Podrobné informace k produktu

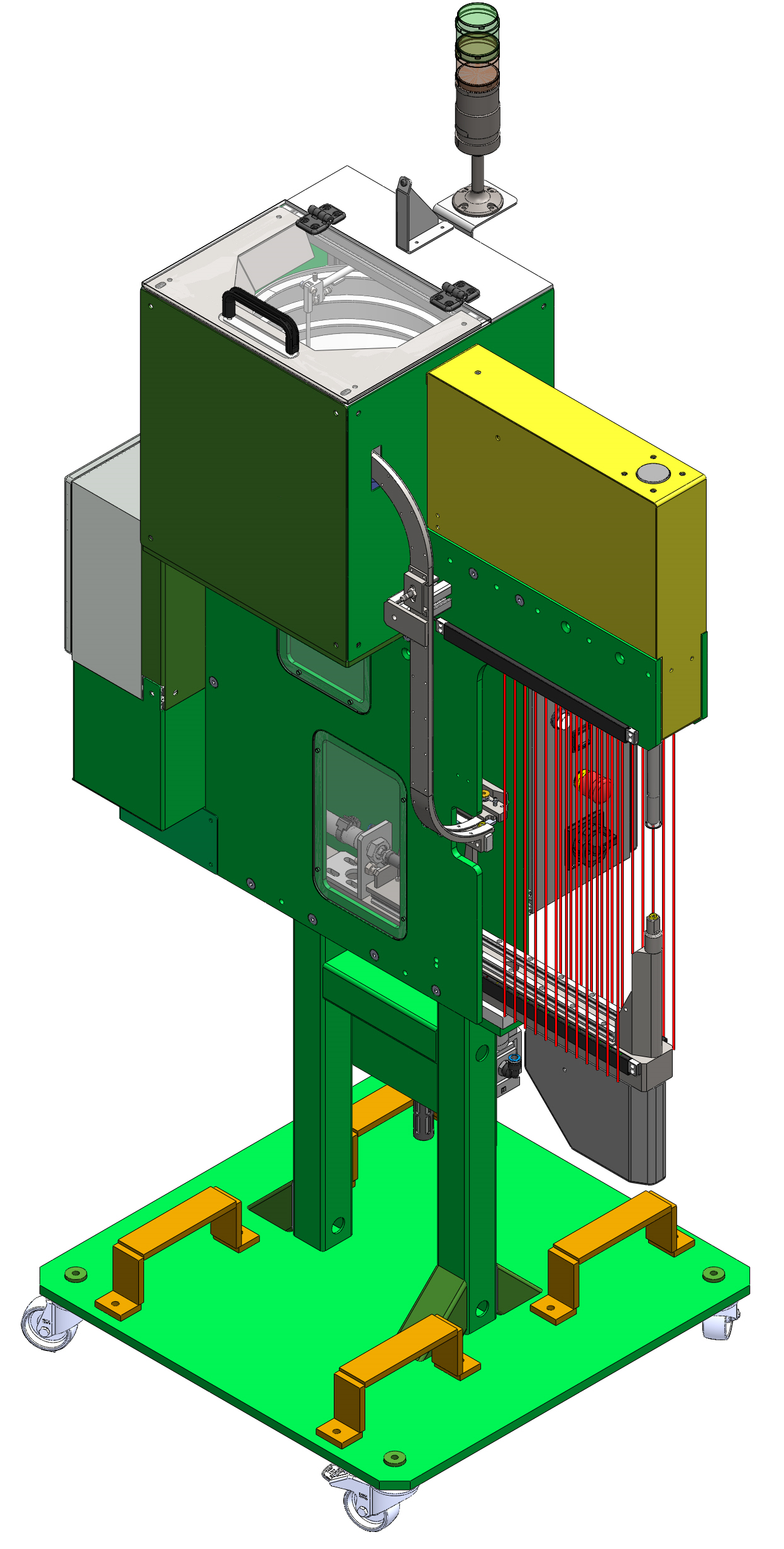

Automatic feeding system - Spring

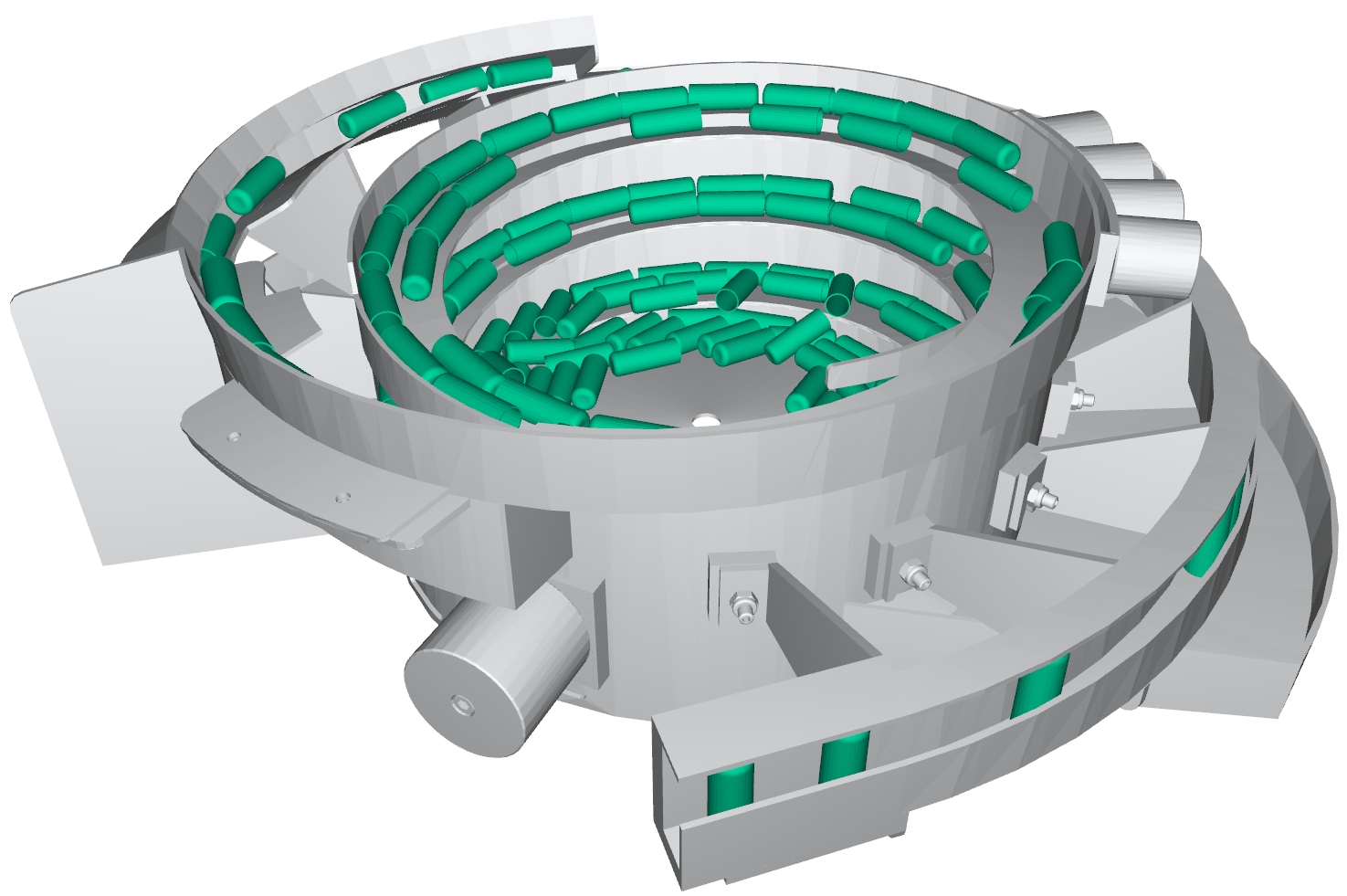

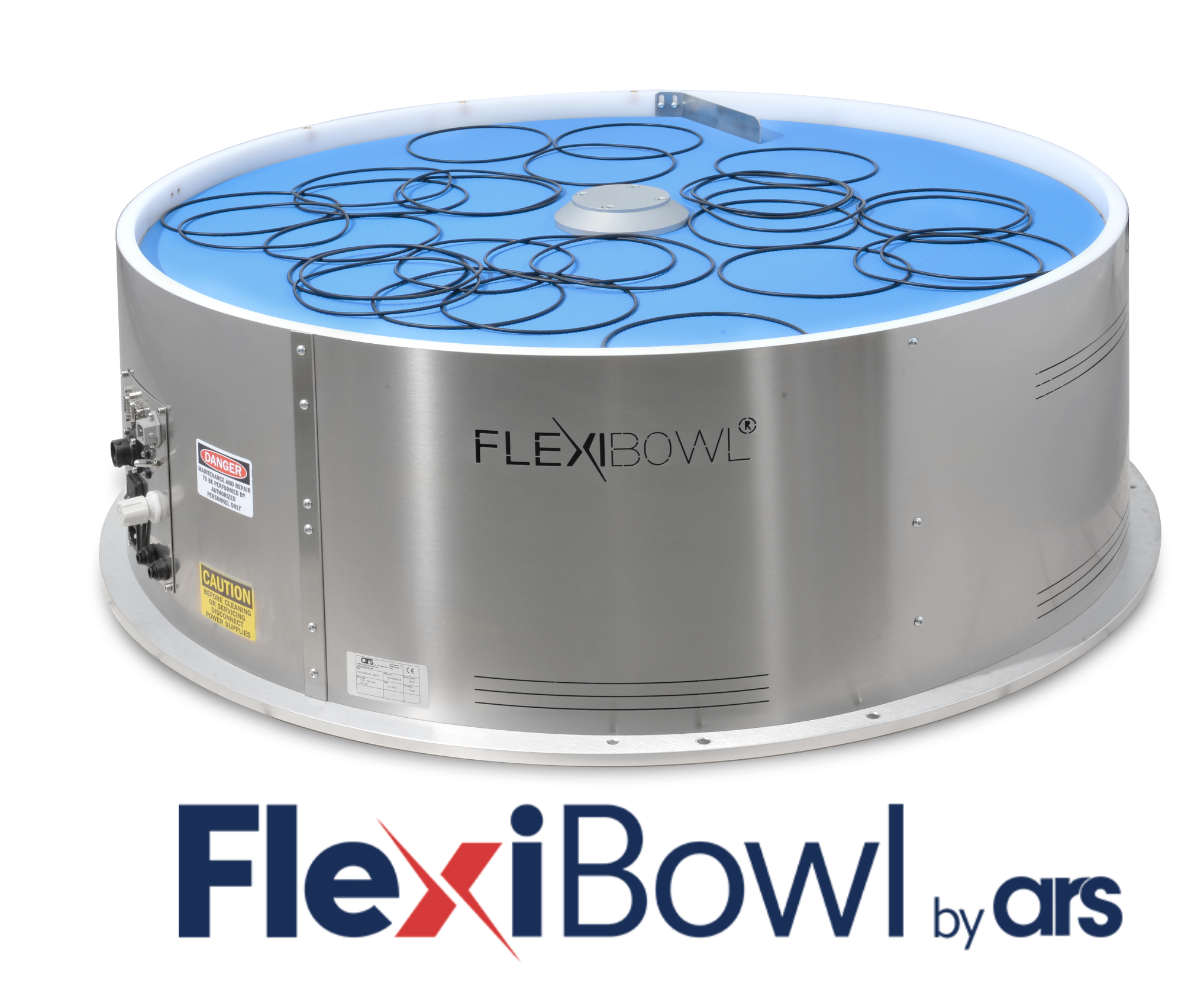

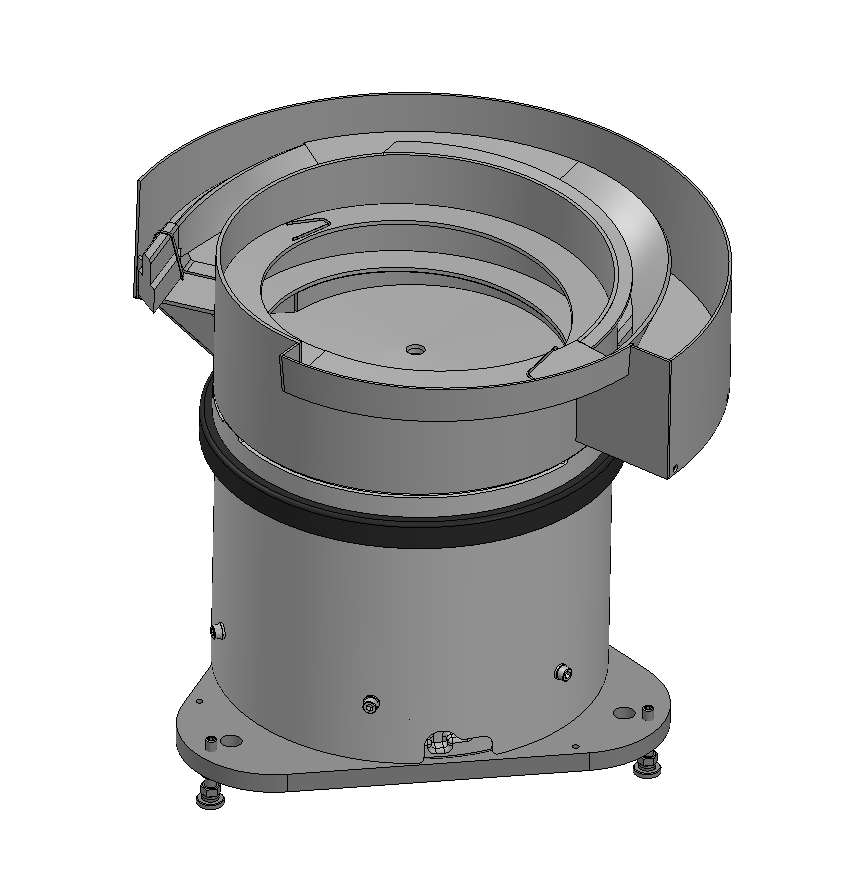

Vibration feeder/sorter system based on RNA SRC-N 250 drive (left or right execution).

- USJ 250 triangle setup plate, for mounting the feeder by 3 screws( set up within +/- 10mm)

- AAG-Z 250 adapter central plate for one screw sorting bowl mounting

- Sorting bowl stainless steel stepped/ conical/ cylindrical - parts orientation due to request

- Surface coating - glued-in sheets/carpets

- Output guiding part -machined ( for precise threshold between bowl and linear rail)

- A compressed air may be used for sorting. Air treatment unit with reduction valve, sol.valve and throttle valves

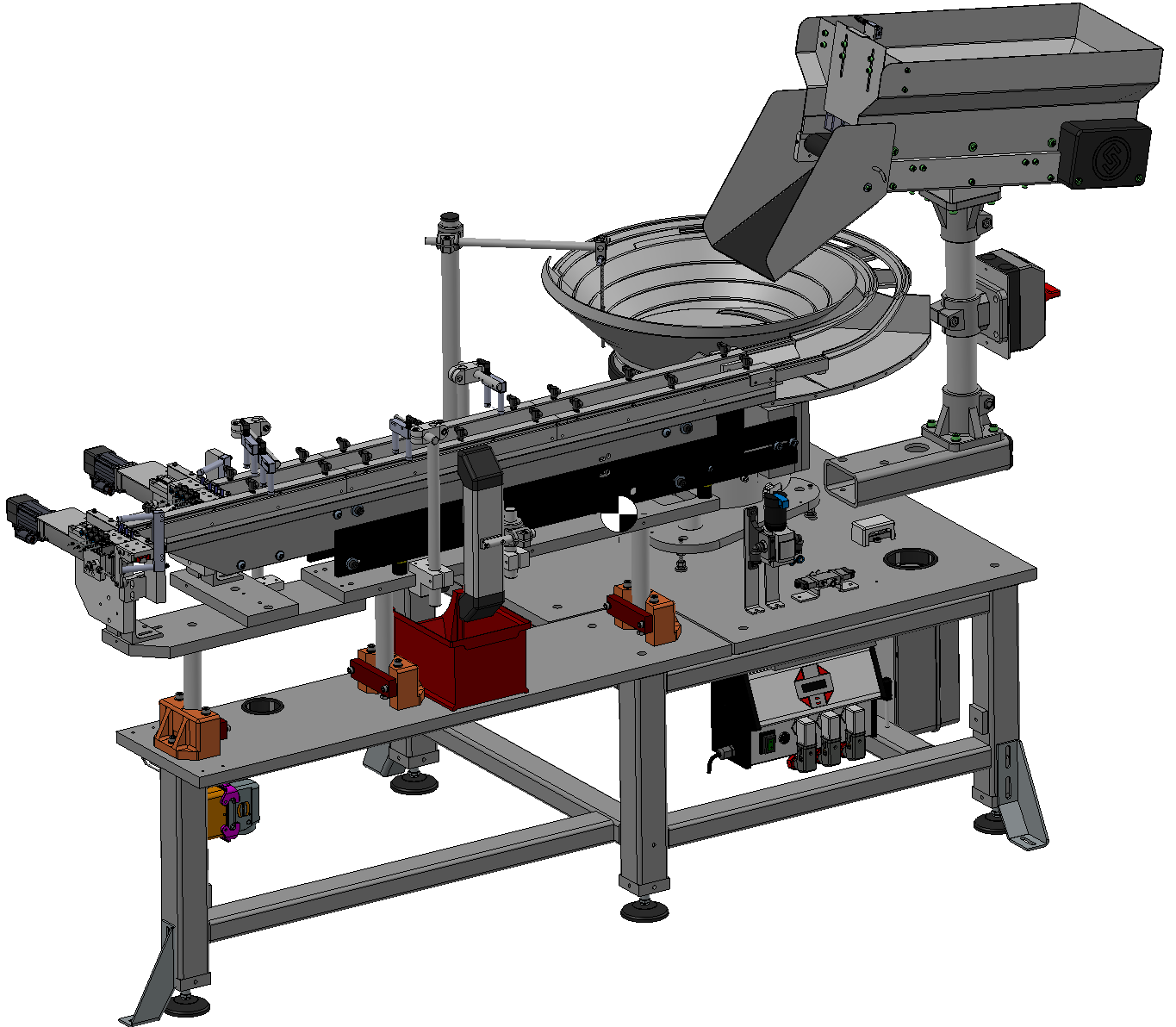

Guiding cumulation rail on vibration drive based on RNA SLL 400 type

- Track length aprx. 700mm

- The RNA SLL400-600 drive ( stand included)

- Guiding elements st.steel or nitrided. optional easy opening top guiding

- Level of parts buffer tracked by Balluff opt. sensor

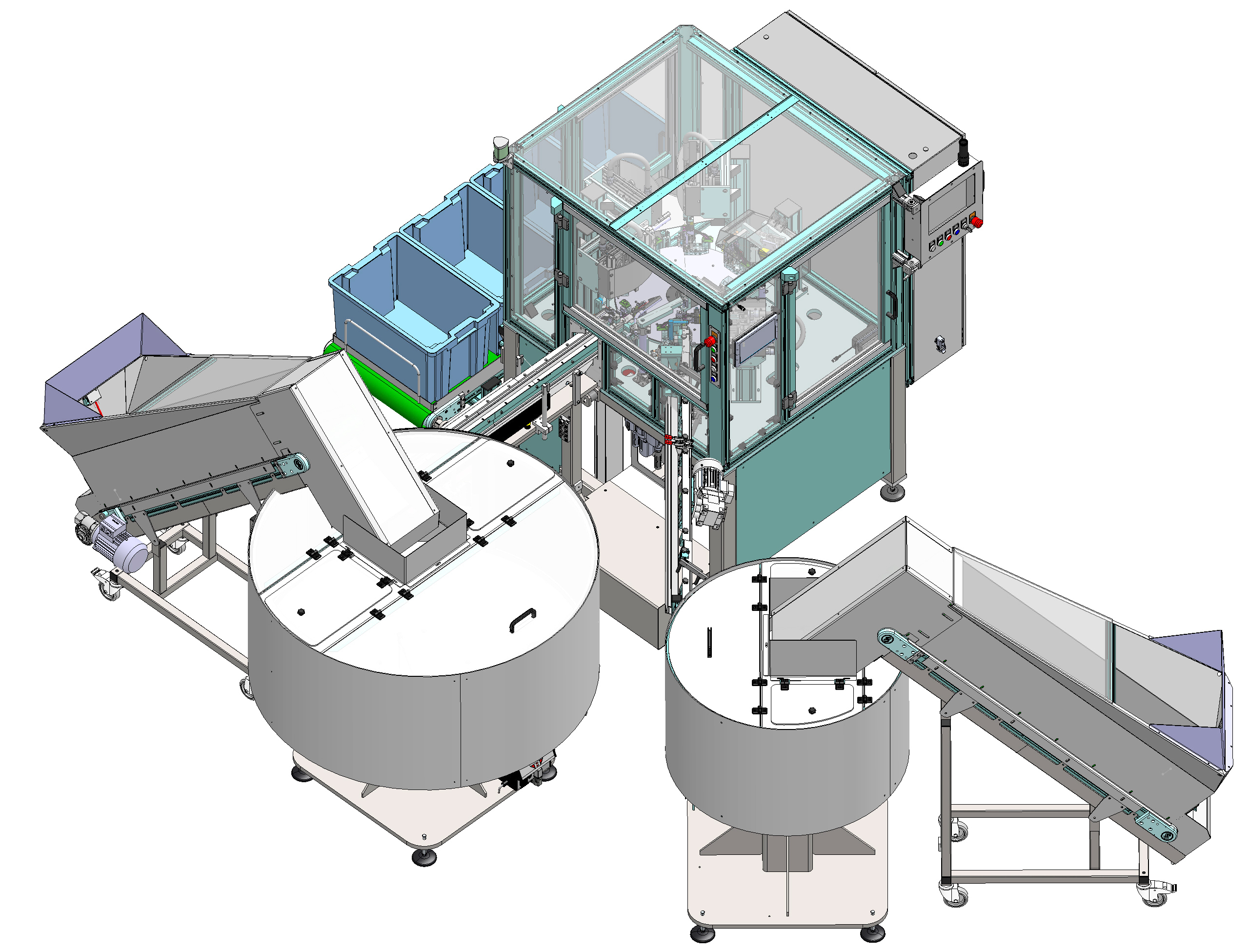

Supply vibration bunkers system with a 5l and 20l volume units

- 20l ones create a parts buffer for an original package of KLT box

- Second 5l bunker creates evenly spread fill dosage

- A stand included for both

- including its own empty and level sensors

The end separation unit

- parts buffered in a linear track enters an end unit where are separated one by on, by pneumatic movement.

- Separation is provided by one movement to upwards - the ejection finger has the middle part free for gripping devi

ce (of superior machine)

- Mounting ( 2 axis setup) bracket included for whole unit ( levelling, setting)

- Sensorics, pneumatic included ( full function provided)

Electrical equippment:

- The ESK 2002 regulator takes care of 3 power outputs (round, linear drive and drive of bunker) same as logic of bowl level sensor and linear line sensor.

- Machine equipped by a small electrocabinet with the main supply, ON/OFF switch, 24V 10A supply.

- The end unit must be controlled by PLC of master machine.

- Interface through ProfiNet Balluff communication hub.

- Wiring diagrams done in EPLAN SW.

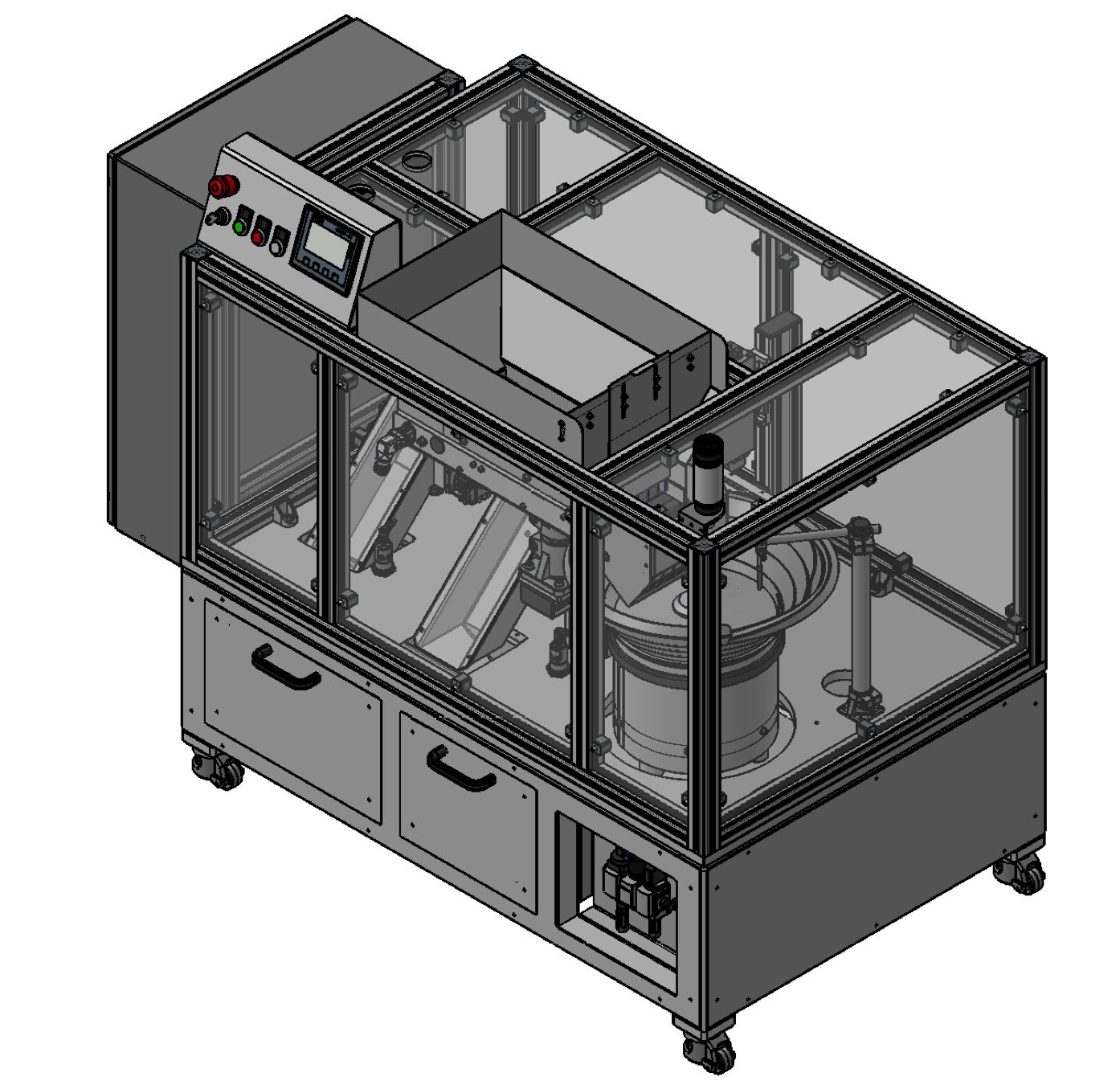

Noise cover in size of RNA SRC-N 250 drive

- fibre glass cover on top. St.steel frame guiding for parts falling from bunker

- Base installation plate/ construction

- Steel painted plate 12mm / constuction 4mm/60 closed profile

- A size and shape can be discussed.

- Painted by RAL shade by customer’s request

- USJ 250 triangle setup plate, for mounting the feeder by 3 screws( set up within +/- 10mm)

- AAG-Z 250 adapter central plate for one screw sorting bowl mounting

- Sorting bowl stainless steel stepped/ conical/ cylindrical - parts orientation due to request

- Surface coating - glued-in sheets/carpets

- Output guiding part -machined ( for precise threshold between bowl and linear rail)

- A compressed air may be used for sorting. Air treatment unit with reduction valve, sol.valve and throttle valves

Guiding cumulation rail on vibration drive based on RNA SLL 400 type

- Track length aprx. 700mm

- The RNA SLL400-600 drive ( stand included)

- Guiding elements st.steel or nitrided. optional easy opening top guiding

- Level of parts buffer tracked by Balluff opt. sensor

Supply vibration bunkers system with a 5l and 20l volume units

- 20l ones create a parts buffer for an original package of KLT box

- Second 5l bunker creates evenly spread fill dosage

- A stand included for both

- including its own empty and level sensors

The end separation unit

- parts buffered in a linear track enters an end unit where are separated one by on, by pneumatic movement.

- Separation is provided by one movement to upwards - the ejection finger has the middle part free for gripping devi

ce (of superior machine)

- Mounting ( 2 axis setup) bracket included for whole unit ( levelling, setting)

- Sensorics, pneumatic included ( full function provided)

Electrical equippment:

- The ESK 2002 regulator takes care of 3 power outputs (round, linear drive and drive of bunker) same as logic of bowl level sensor and linear line sensor.

- Machine equipped by a small electrocabinet with the main supply, ON/OFF switch, 24V 10A supply.

- The end unit must be controlled by PLC of master machine.

- Interface through ProfiNet Balluff communication hub.

- Wiring diagrams done in EPLAN SW.

Noise cover in size of RNA SRC-N 250 drive

- fibre glass cover on top. St.steel frame guiding for parts falling from bunker

- Base installation plate/ construction

- Steel painted plate 12mm / constuction 4mm/60 closed profile

- A size and shape can be discussed.

- Painted by RAL shade by customer’s request

Kompletní podávací systémy řady 250

Automatic feeding system - Spring

V24-064-1-00-000

Skladem 0 ks

Pro nákup zboží je nutná registrace.

| Kód dílu: | V24-064-1-00-000 |

|---|---|

| Dodací lhůta: | 0 |

| Jednotka dodací lhůty: | Dny |

Související produkty

-

Skladem 0 ks

Pro nákup zboží je nutná registrace.